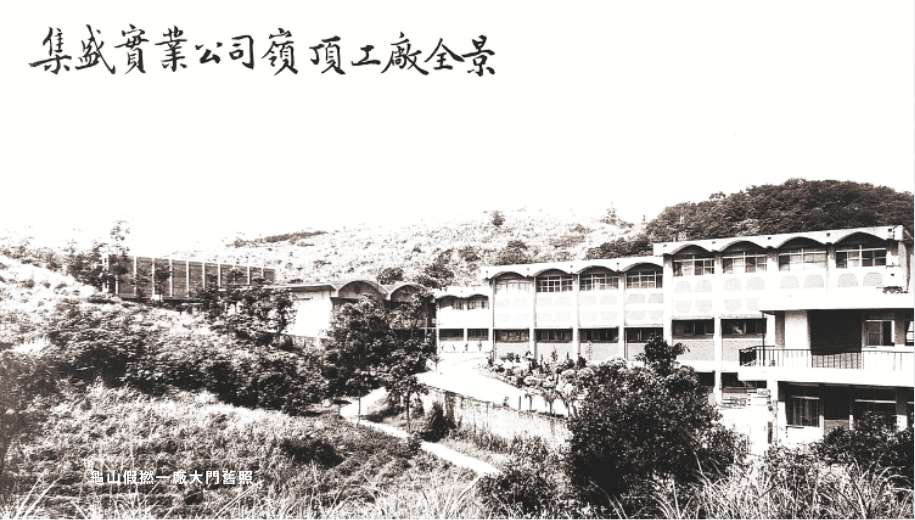

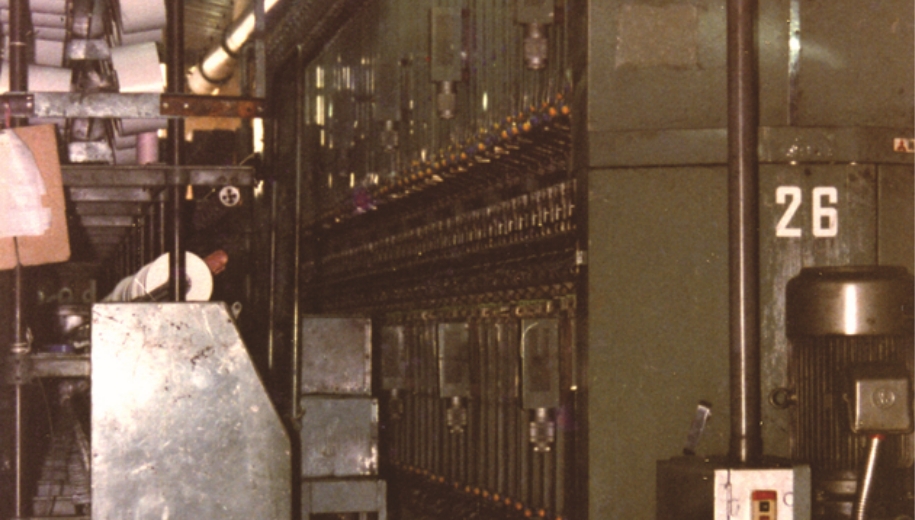

以特有差異化、客製化的產銷模式,為全球高性能尼龍絲主要供應商。

A primary supplier of high-performance nylon filament around the world supported by a diversified, custom production model.

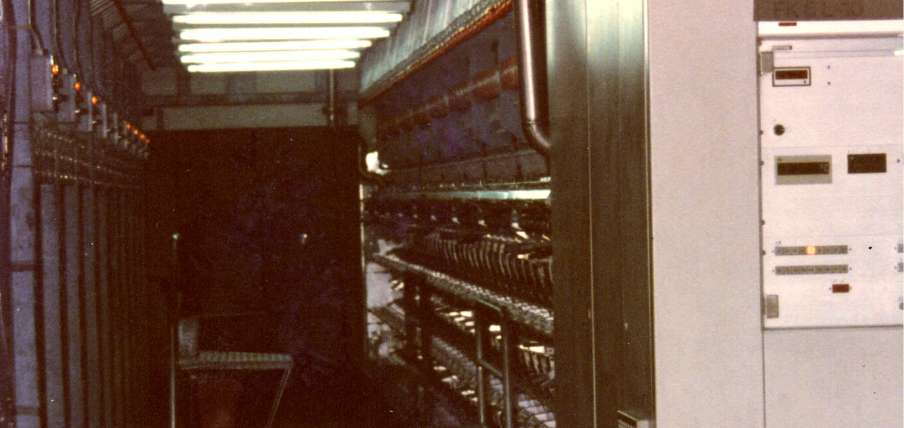

投入環保纖維絲加工,並在功能性纖維如高彈性纖維、長效抗菌纖維及涼爽纖維等方面均有開發。

ZIG SHENG actively supports the texturization of recycled yarns and has developed several functional textiles including high tenacity yarn, Long-lasting anti-microbial yarns, and cooling yarns.

台灣前3大尼龍粒生產商。尼龍粒主要用於工程塑膠、薄膜及工業/紡織用絲等產業領域。

ZIG SHENG is one of the three largest nylon chip manufacturers in Taiwan. Our chips are used mainly in industrial fields, such as engineering plastic, film, industrial yarn, and textile grade yarn.

複材產品主要用於汽車零配件、工業零件、電子電器、包材等領域。

ZIG SHENG compound products are primarily applied in automotive parts and accessories, industrial parts, electronics and appliances, packaging etc.

非對稱膜的一種,可來截留水中的微粒、細菌等,使其不能通過濾膜而被去除。

An asymmetrical membrane that can be inserted into a water source to ensure microparticles and bacteria don't get caught in the filter and can be properly eliminated.

創新開發

Innovation and

Development

環保原液染色纖維

Sustainable dope dye yarn

尼龍6膠原蛋白纖維

Nylon 6 collagen yarn

親水涼爽尼龍纖維

Hydrophilic cooling nylon yarn

能量尼龍纖維

Energizing nylon yarn

聚酯機械彈性纖維,如柔軟有彈性的舒芙蕾

A warm and inviting mechanical stretch polyester yarn that's soft and springy like a fresh souffle

輕量快乾的聚丙烯纖維

A rough and tough yarn with a wide range of applications

應用範圍

Range of Applications

纖維事業部

Fiber Business Division

化材事業部

Chemical Materials Division

尼龍粒

Nylon Chips

複合材料

Polyamide (PA) Compounds

中空纖維膜

Hollow Fiber Membrane

投資人專區

Investor Relations

財務資訊

Financial Information